ROMACO NOACK - Blister Line - N920 + C150 + PEWOPACK250 + CT2000

Specifications

| Manufacturer | ROMACO NOACK |

| Model | N920 + C150 + PEWOPACK250 + CT2000 |

| Year | 2009 |

| Condition | Used |

| Serial Number | MLTC-10-25-1853_25-1849_25-1845_25-1842 |

| Stock Number | MLTC-0010-WH |

Description

ROMACO NOACK BLISTER LINE

composed of

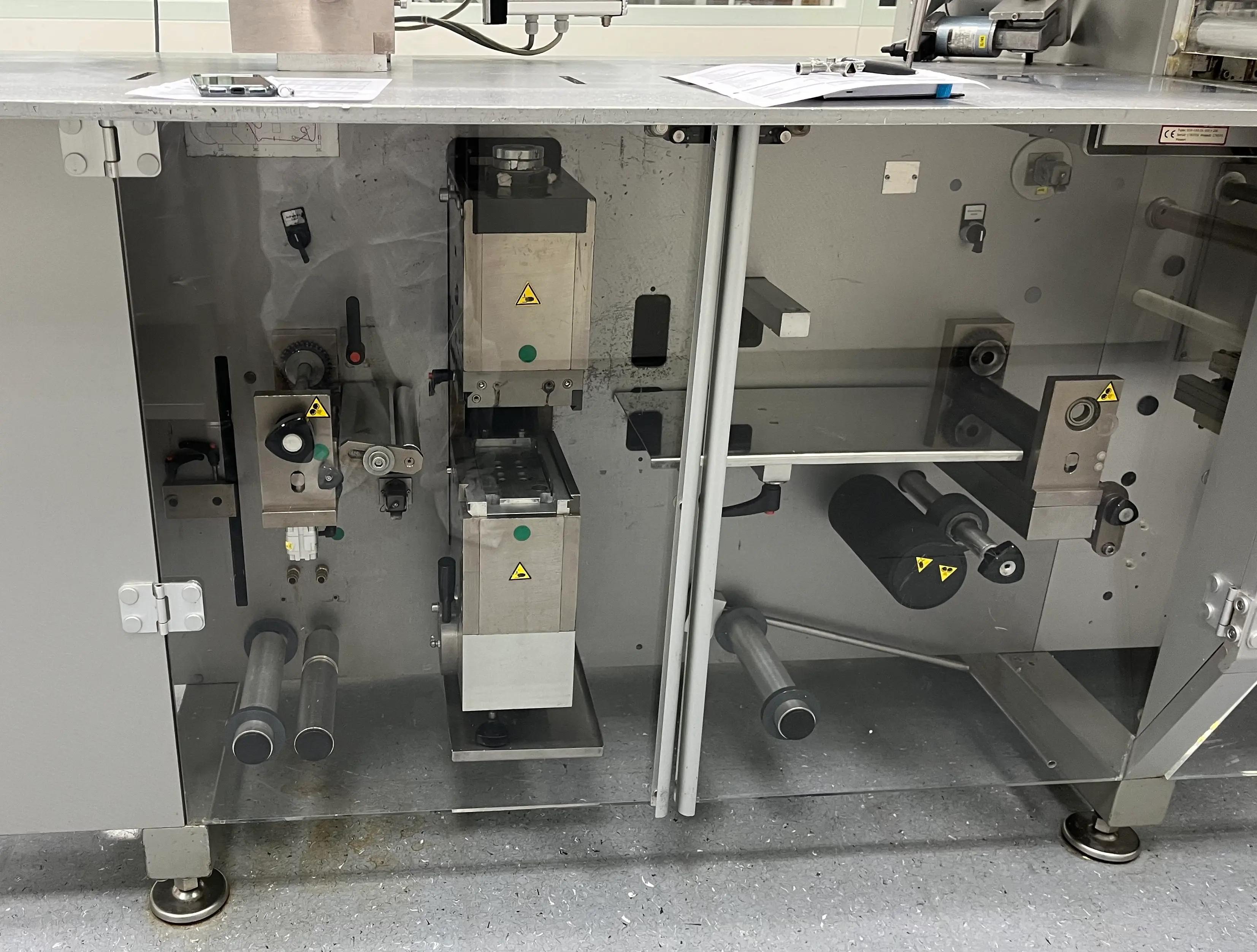

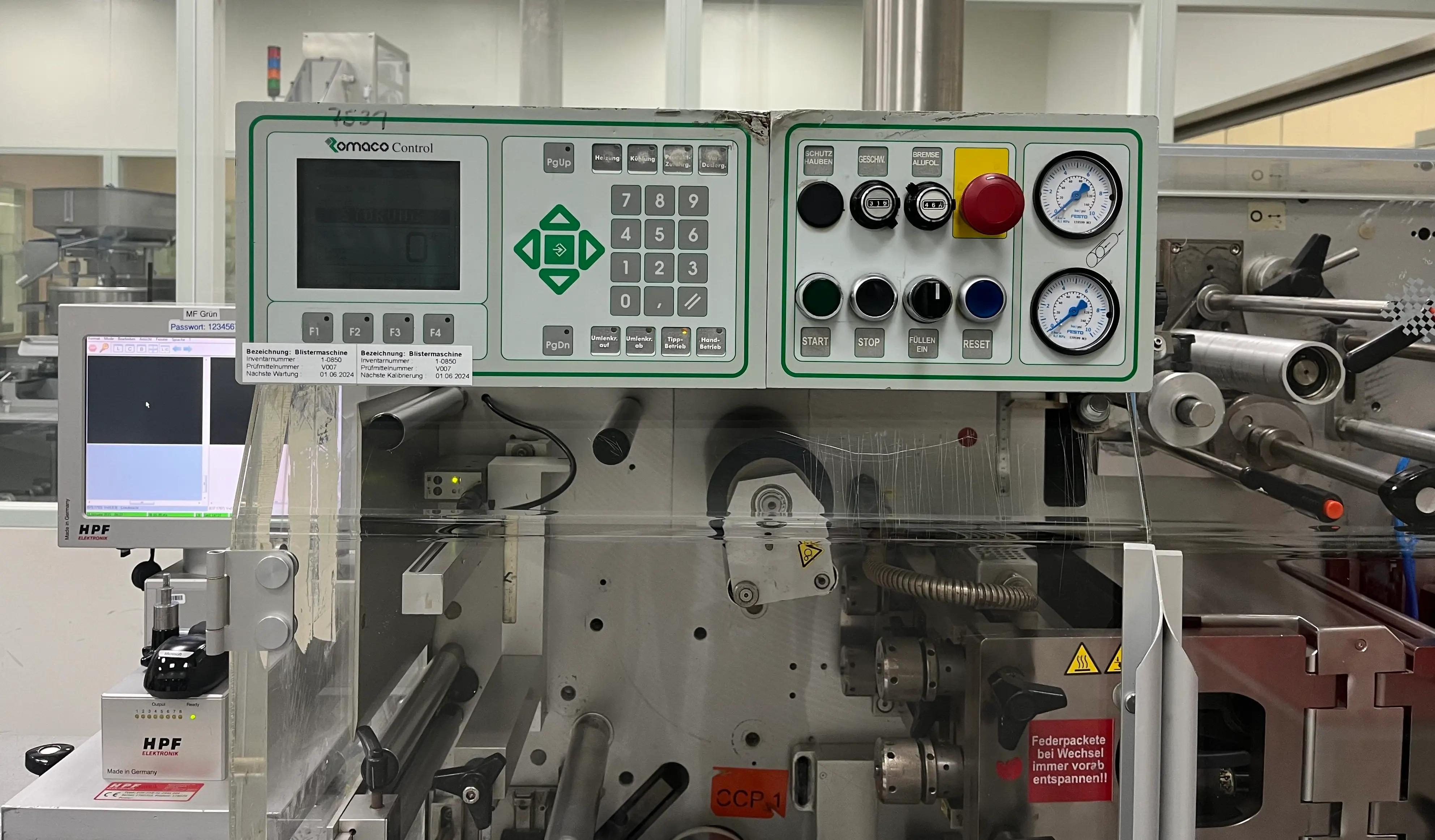

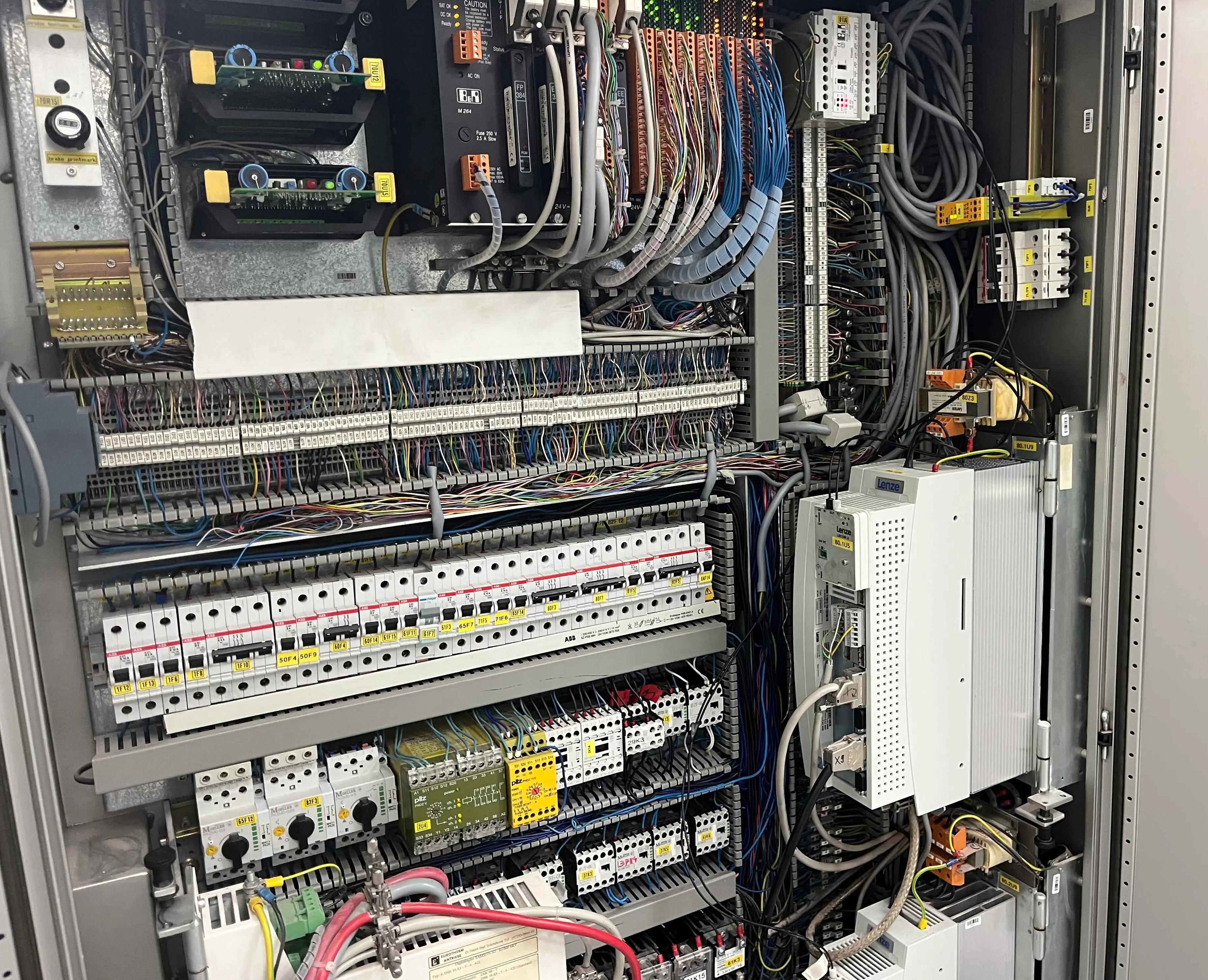

1) ROMACO NOACK PACKAGING MACHINE, MODEL N 920

Year of construction: 2010

Rotary blister packaging machine. With a 360° sealer. Fully cGMP compliant.

- XML control with touchscreen control panel

- With QuickFeed

- Balcony design

- Easy integration of online printing and security systems

PRODUCTION CHARACTERISTICS

- Output: up to 500 blisters/min

- Max film width: 210 mm

- Max forming depth: 12 mm

- Max forming cycles: 100/min

- Max film forming roller diameter: 700 mm

- Max diameter of coating film roll: 280 mm

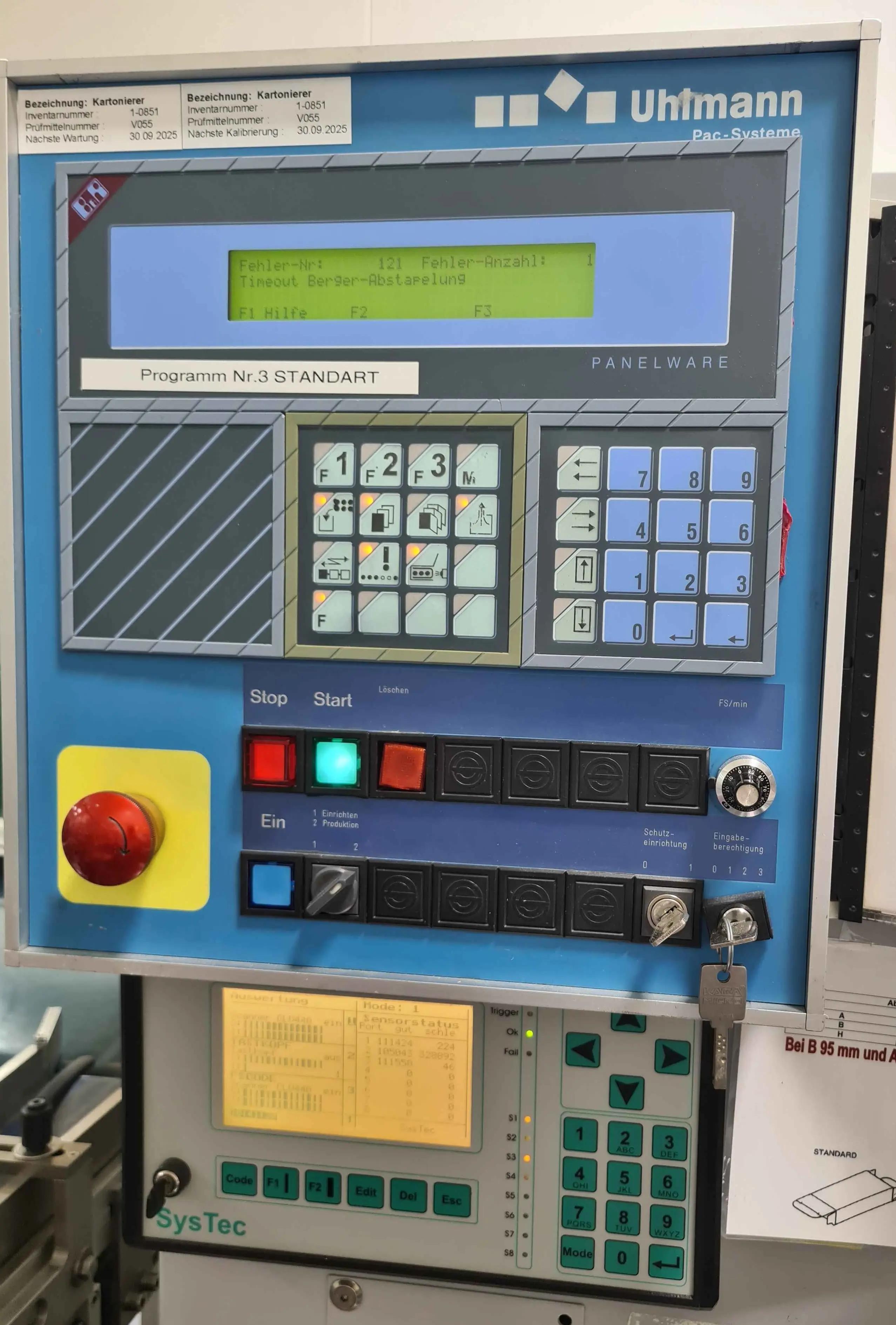

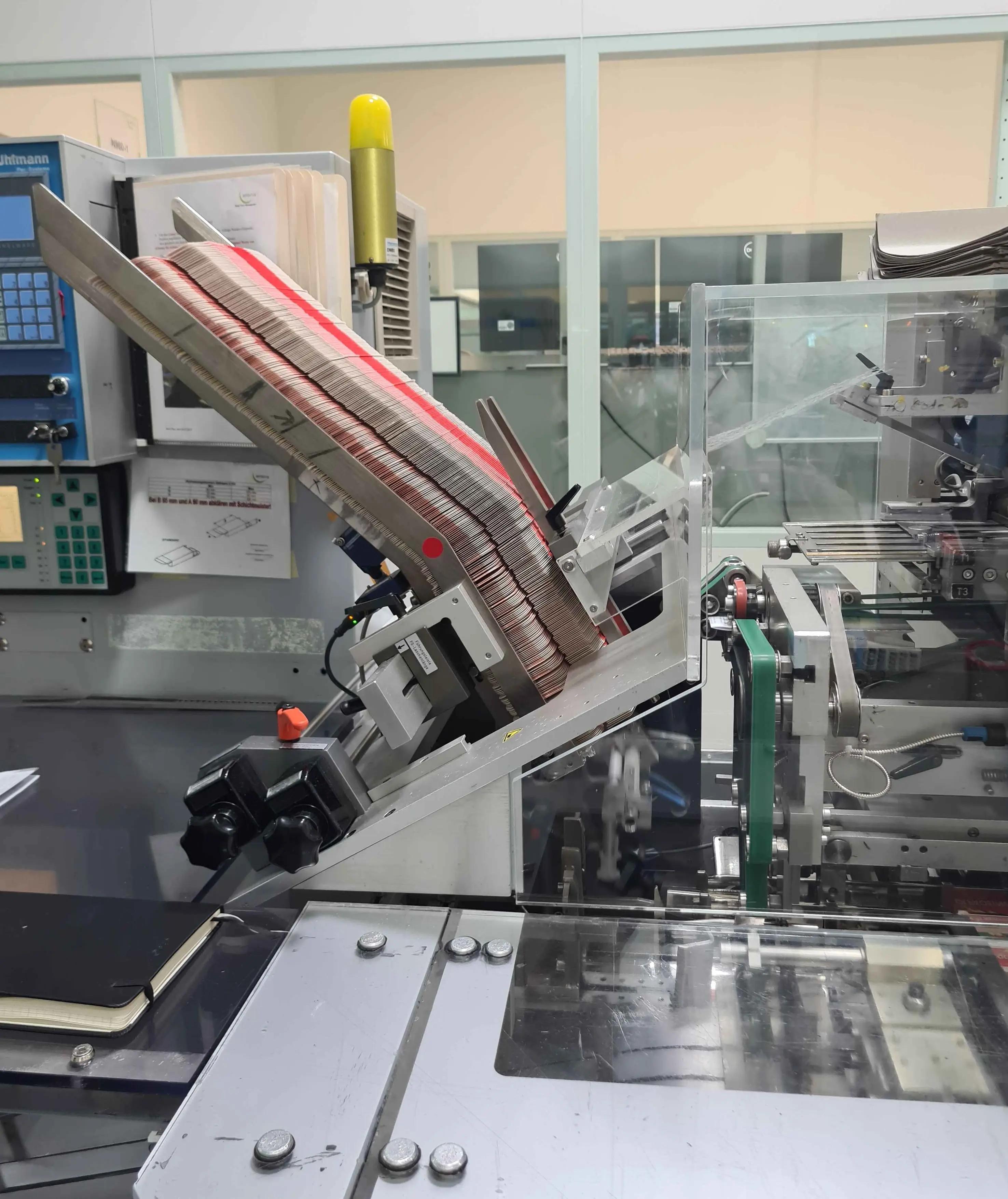

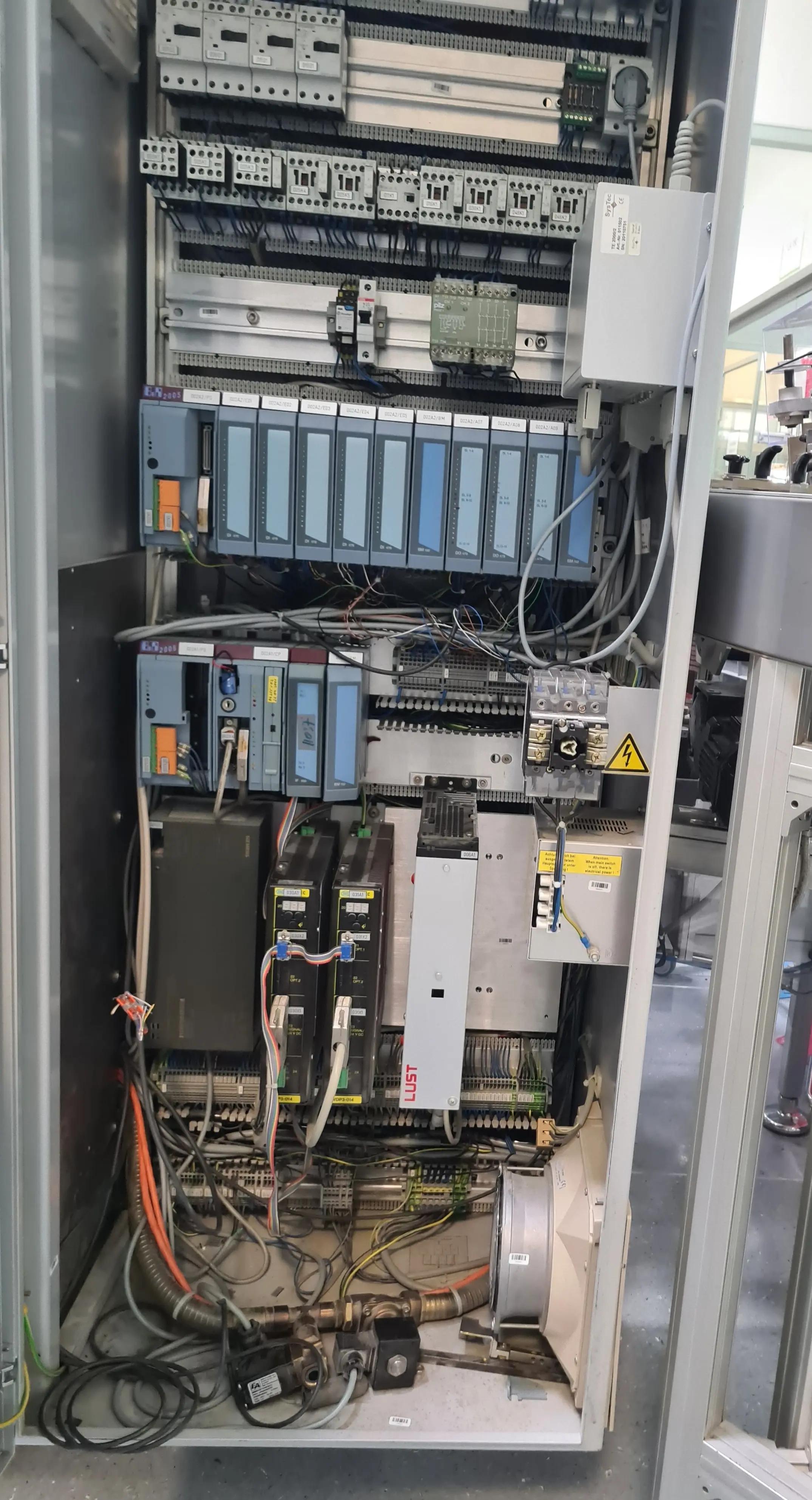

2) UHLMANN CARTONER, MODEL C150

Year of construction: 2004

Intermittent motion cartoner for small and medium batches of blisters.

PRODUCTION CHARACTERISTICS

- Output: 150 cartons/min (max)

- Maximum carton dimensions: 100 x 85 x 150 mm

- Maximum number of blisters: 10

- Maximum height of blister stack: 80 mm

- Closure types: Interlocking and hot-melt glue

- Application area: Blister

- Type of operation: intermittent

- Pitch: 5''

3) PESTER PACKAGING MACHINE, MODEL PEWO PACK 250:

Year of construction: 2000

Automatic packaging machine.

PRODUCTION CHARACTERISTICS

- Output: up to 80 packs/min

- Pack dimensions: 60 x 30 x 60 mm (min); 360 x 180 x 250 mm (max)

- Film width: min.: 50 mm - max.: 250 mm

- Film thickness: min.: 25 μm - max.: 100 μm

- Roll diameter: max.: 300 mm

ENERGY CONSUMPTION

- Power supply: 3x400V + N + PE / 50Hz

- Operating pressure: 5 bar

- Usable film: PE material

4) SEALING MACHINE, MODEL T-4000

For top and bottom welding. With automatic tilting of tabs. Can be adapted very easily to the current box dimensions. Adjustment can be made from both sides.

- Power control with SOCO SYSTEM controller

- Simple and cost-effective maintenance

- Wide range of accessories, e.g. wheels with brakes, packing tables and conveyor belts

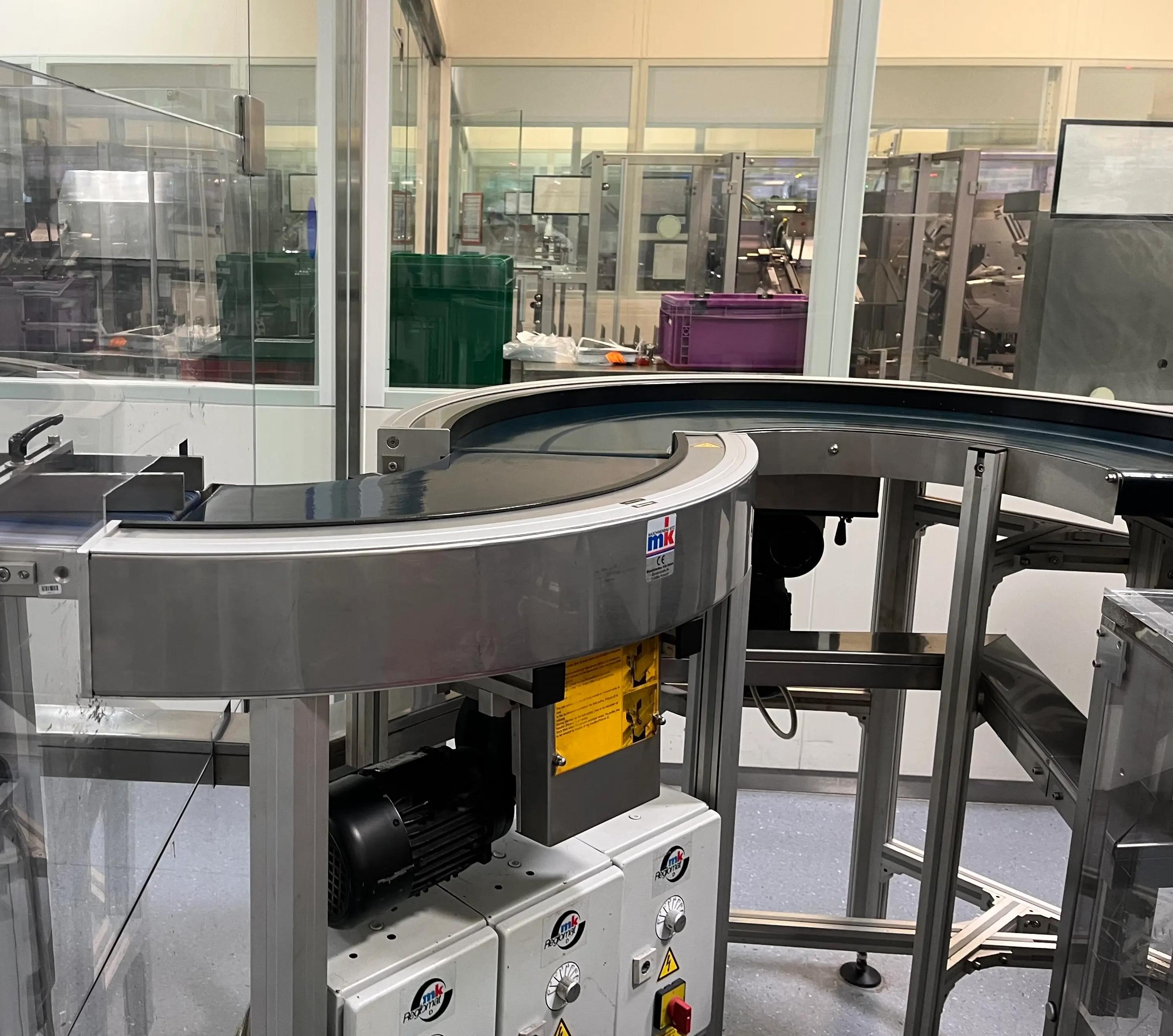

5) CHRIST STRIP COLLECTION TABLE, MODEL CT2000

Year of construction: 2009

Fully automatic strip collection table for temporary storage of products.

- Easy-to-clean stainless steel casing

- Ergonomic design with ample space for the operator's feet and knees

- Compact, high quality balcony design

- Automatic recognition of a full table and stop of upstream machines

ENERGY CONSUMPTION

- Operating voltage: 1x230 V; 50 Hz

- Control voltage: DC 24 V