BOSCH - Ampoules Filling Line - RQU 2160 + HQL 3420 + ALK 4080 + DRN 3010

Specifications

| Manufacturer | BOSCH |

| Model | RQU 2160 + HQL 3420 + ALK 4080 + DRN 3010 |

| Year | 1992 |

| Condition | Used |

| Serial Number | MLTC-10-25-1578 |

| Stock Number | MLTC-0010-WH |

Description

BOSCH AMPOULE LINE

Year of construction: 1992

composed of

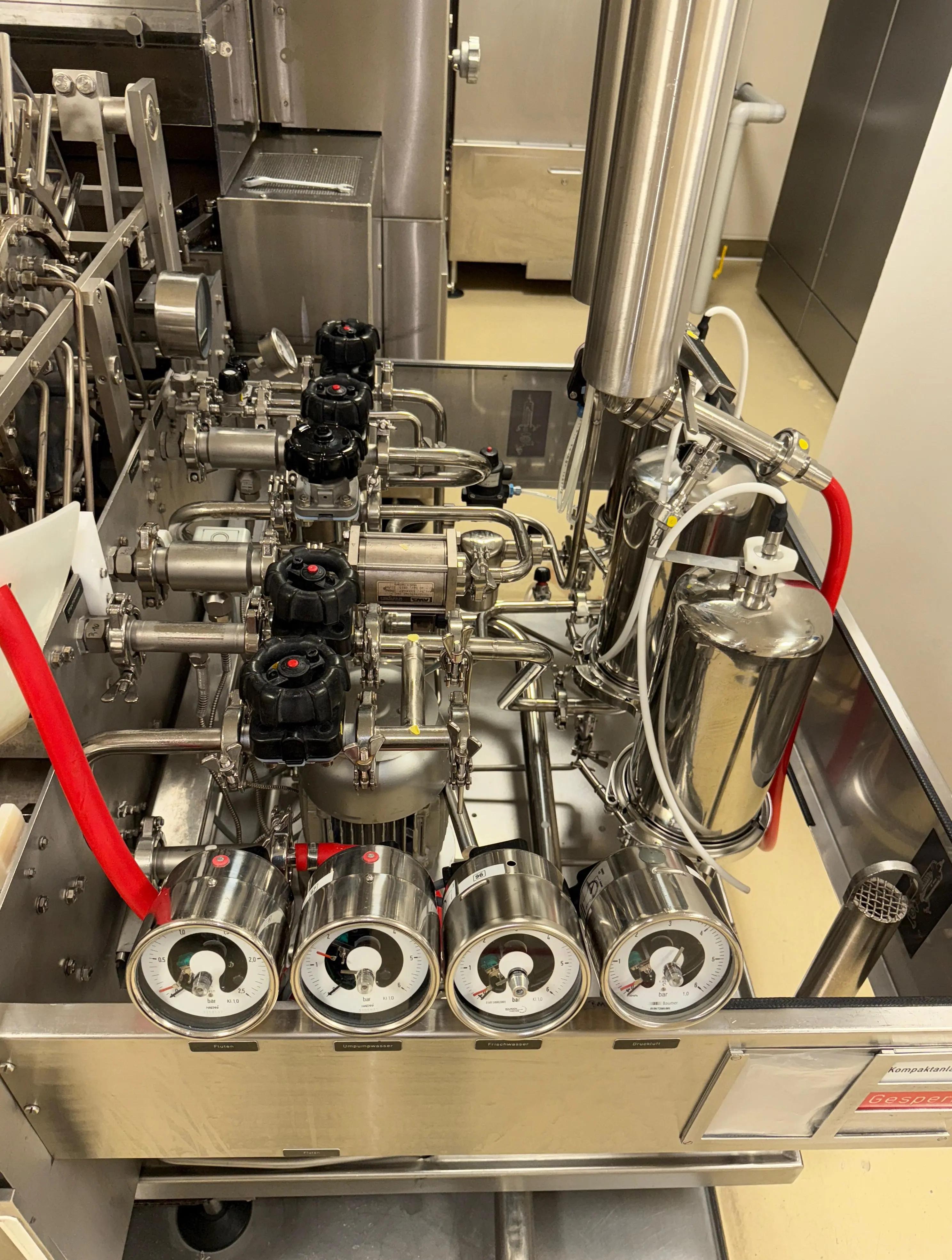

1) BOSCH RQU 2160 WASHER AND DRYER

Cleaning and drying machine for fast and accurate removal of particulate matter.

- the swivel design allows for a small footprint and ease of operation

- the rotary heads can be configured for a wide range of formats

- processing ranges and capacities depend on individual containers, line integration, etc. construction according to GMP

PRODUCTION CHARACTERISTICS

- Output: from 13.500 to 24.000 pcs/hr

- Filing quantity: 1/2/5/10 ml

2) BOSCH HQL 3420 STERILIZER

Tunnel for sterilizing glass containers before aseptically filling them. Utilizes forced air at temperatures up to 350 °C.

- guarantees consistent precision necessary for validation, qualification, and reliable production capacity

- inside the tunnel, the air feeds the supply and cooling section through the pre-filters and the air particle filters in the separate areas of the tunnel

- below the conveyor, the air is directed back through a recirculation duct to the fan

- equipped with an automatic overpressure control in the cooling section

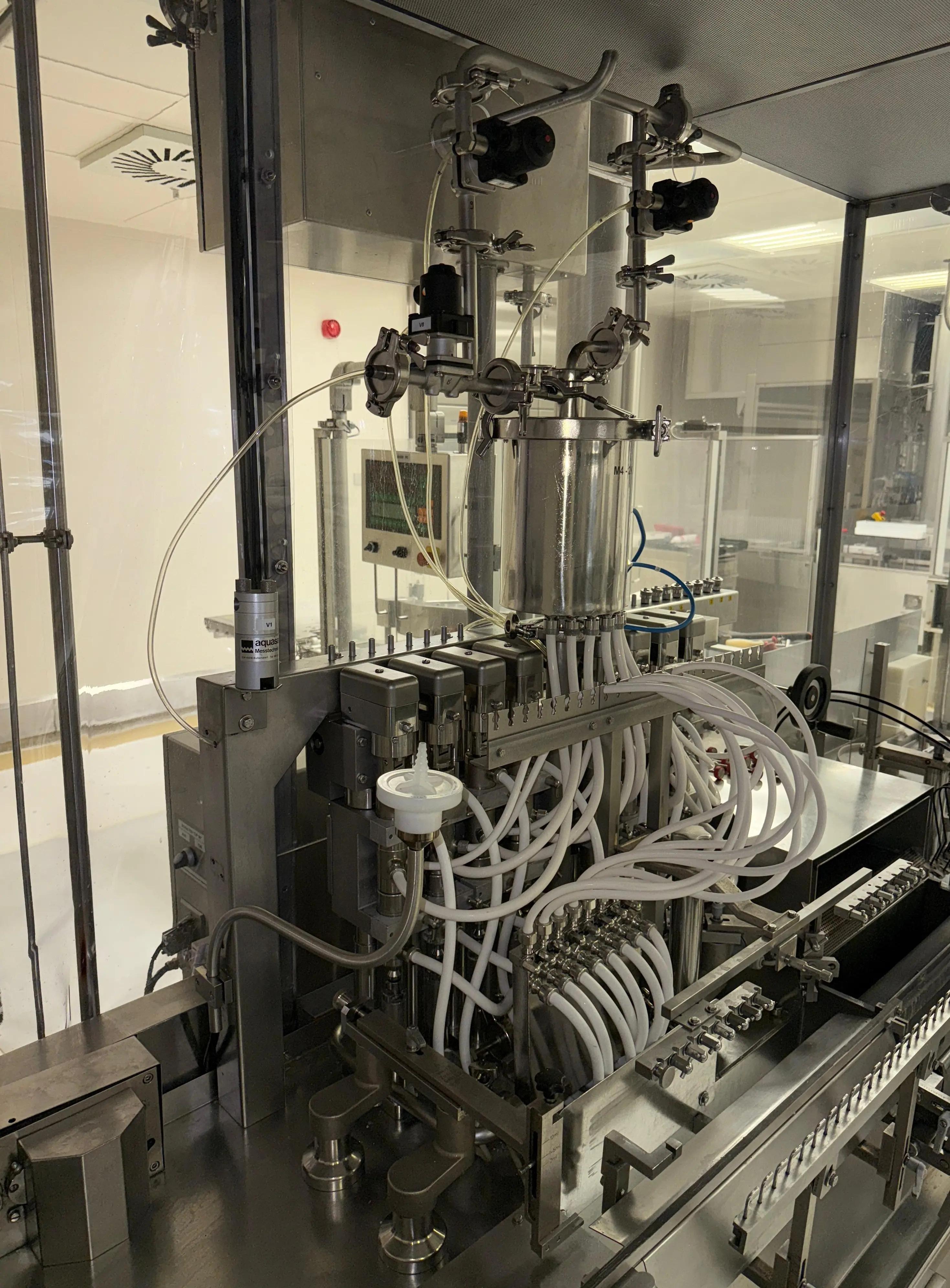

3) BOSCH ALK 4080 AMPOULES FILLER

Purpose-built for filling ampoules according to the standards of pharmaceutical production. Adaptable to various container sizes and formats, can handle different product viscosities.

- employs precise dosing systems and control mechanisms to ensure consistent fill volumes

- user-friendly interface to simplify setup, operation, and monitoring

- robust construction and use of high-quality materials guarantee longevity

- straightforward routine maintenance

MANUFACTURING CHARACTERISTICS

- Production: 400 ampoules/min

- Container diameter: From 9 up to 18 mm

- Container height: From 60 up to 110 mm

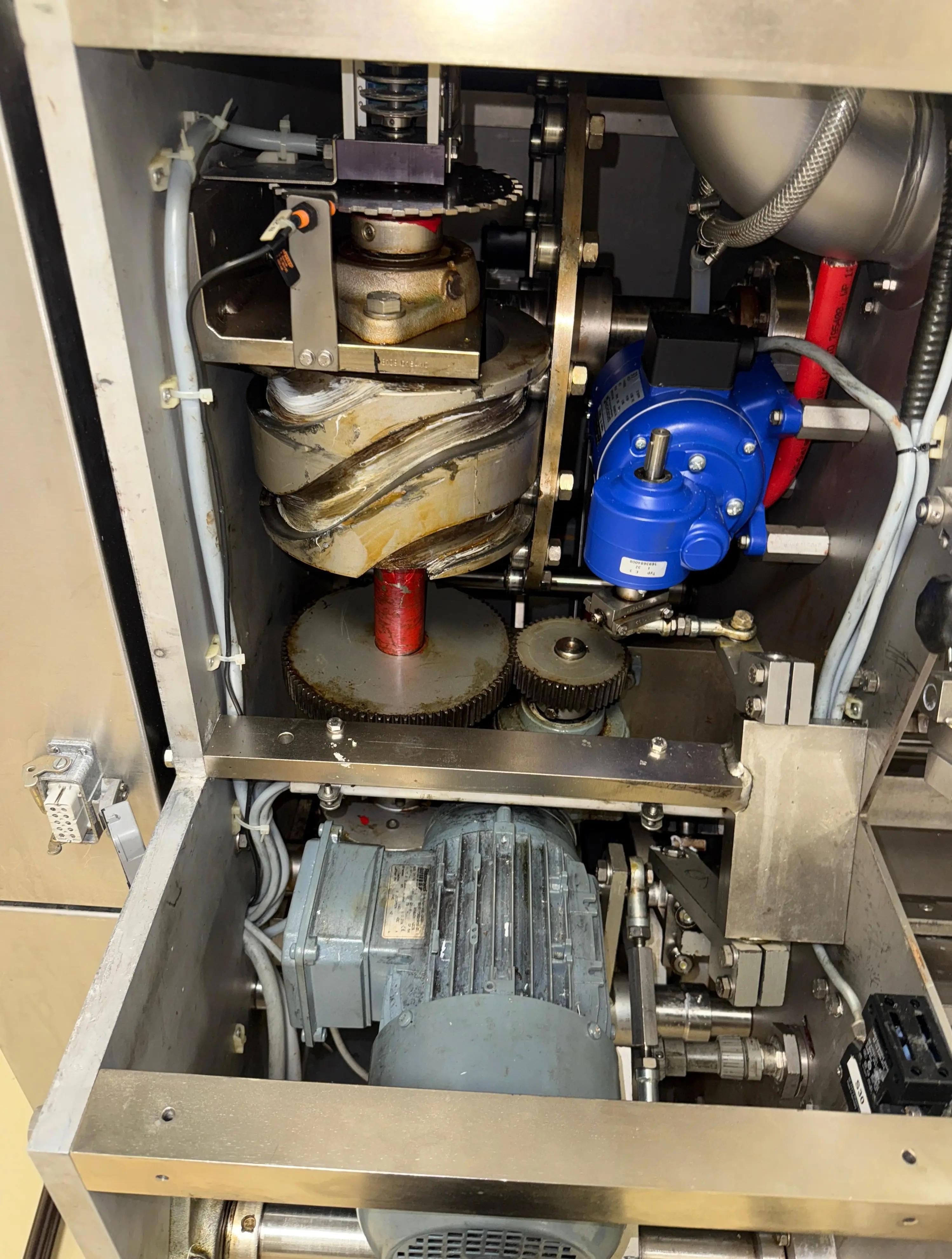

4) BOSCH DRN 3010 AMPOULE COLOR RING CODING MACHINE

Designed to be used directly after the filling and sealing process, to colour ring code the ampoules. Up to 4 plug in color ring units, for up to 6 colours for electronic code reading, resulting in more than a thousand different electronically readable ring combinations.