BAUSCH+STRÖBEL - Liquid Filling Line - ESM 10010

Specifications

| Manufacturer | BAUSCH+STRÖBEL |

| Model | ESM 10010 |

| Year | 2015 |

| Condition | Used |

| Serial Number | MLTC-D-B020 |

| Stock Number | MLTC-0001-WH |

Description

BOTTLE WASHING/STERILIZING/FILLING/CLOSING LINE BAUSCH & STRÖBEL

Year of construction: 2015

System for filling infusion bottles for lipid emulsions and closing with rubber stopper and aluminium cap.

The entire plant from 2015, but never put into operation. Originally factory-packed and complete in wooden crates.

- Parts in contact with product made of stainless steel AISI 316L

- Connection 230/400V/50Hz

- Output max. 5,800 bottles/h, with sterilisation in DHT 62125 and CFDA-conditions 4,000 bottles/h (100 ml), 2,250/h (250 ml), 1,500/h (500ml)

- Usable bottle sizes (depending on formats): diam. 16-98 mm, height 85-180 mm

- Available formats for glass bottles: 100, 250 and 500 ml

- Usable rubber stoppers (depending on formats): diam. 12-35 mm, height 6-18 mm

- Usable crimp caps (according to formats): diam. 12-40 mm, height 6-18 mm

- PLC Siemens S7

- HMI Bausch & Ströbel OVD (Operation, Visualisation, Data collection and Evaluation) basic operating 15 inch touch panel PC

- Operating system Windows Embedded Standard 7

- Menu languages D, E, CH

- User administration according to 21 CFR part 11 EU GMP Annex 11

- Ethernet interface

- Compact Flash Card (CF)

- UPS for HMI

System consisting of:

Washing machine AWU 6030 (ultrasonic)

- Max. temperature 85°C

- 8 stations

- Bottle feeder in bulk

- Pre-cleaning by ultrasonic device

- Main cleaning by ultrasonic device

- Recirculation

- 3 different cleaning liquids can be used

- PLC Siemens S7-300, servo motors Jetter with Jetter Control

Sterilising tunnel DHT 62125

- 1 preheating zone with prefilter F5 according to DIN EN779

- 5 sterilising zones slightly turbulent LF with filters class H14 and H13 according to DIN EN1822

- 2 cooling zones length 2,700 mm with pre-filter F5 according to DIN EN779 and slightly turbulent LF with filters class H14 according to DIN EN1822

- Monitoring for airflow with Photohelic differential pressure gauges

- Monitoring for filters with Magnehelic differential pressure gauges

- Monitoring for temperature with PT 100

- 12-channel recorder

- PLC Siemens S7-300, AC/DC motors

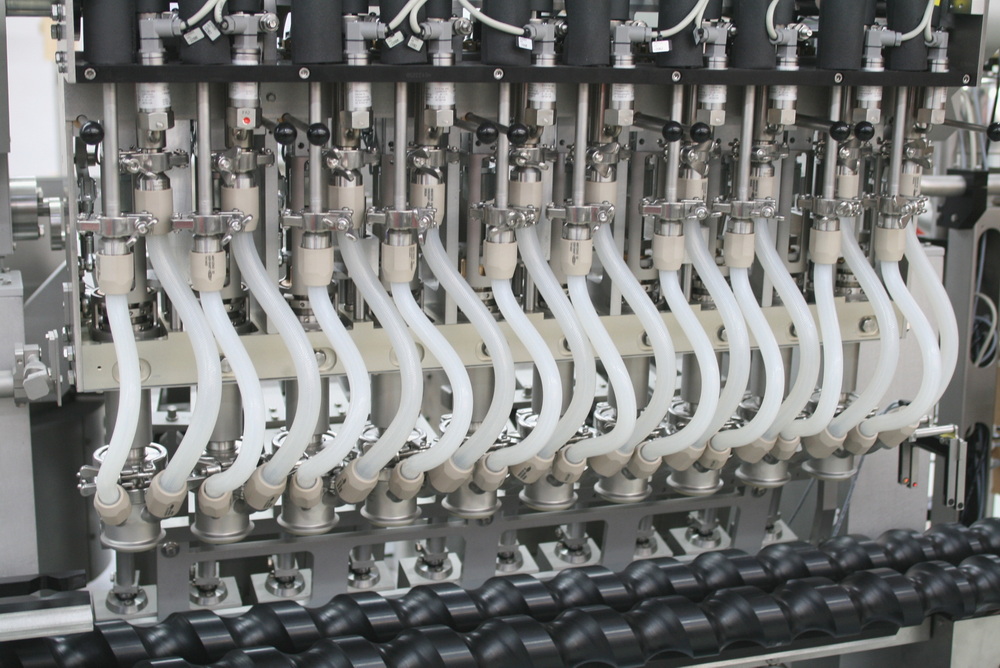

Filling/gassing/evacuation/plugging machine ESM 10010 (CIP/SIP)

- Dosing tank 100L, pressurised

- 10-position intermittent bottle transport in line

- 2 sorting pots for cap feed with 2x5 stopper feed rails

- Gas flushing during filling

- Time/pressure filling system (low shear forces)

- Electronically adjustable needle movements for overhead filling

- Evacuation before capping with rubber stoppers, alternatively with or without gas exchange

- CIP/SIP system (Cleaning in Place / Sterilising in Place) for the entire dosing system incl. 100L dosing tank

- PLC Siemens S7-400, servo motors Jetter with Jetter Control

Closing machine for aluminium caps (crimp caps) RVB 4080

- Cap hopper

- Sorting bowl

- 8 stations capping unit in rotary cycle

- PLC Siemens S7-300, AC/DC motors