GRONINGER - Linea Riempimento Liquidi - DTE-600 + ZSB-600 + DE-100 + AAVK 300 + KFVG 201

Specifiche

| Produttore | GRONINGER |

| Modello | DTE-600 + ZSB-600 + DE-100 + AAVK 300 + KFVG 201 |

| Anno | 2000 |

| Condizione | Usato |

| Numero di serie | MLTC-011-0006 |

| Numero di magazzino | MLTC-0012-WH |

Descrizione

LINEA DI RIEMPIMENTO E TAPPATURA GRONINGER

Principalmente una riempitrice e tappatrice monoblocco usata. Occasionalmente utilizzata per brevi tirature, è ancora in ottime condizioni con poche ore di funzionamento.

CARATTERISTICHE DELLA LINEA

- Per il riempimento di liquidi, compresi prodotti a base alcolica

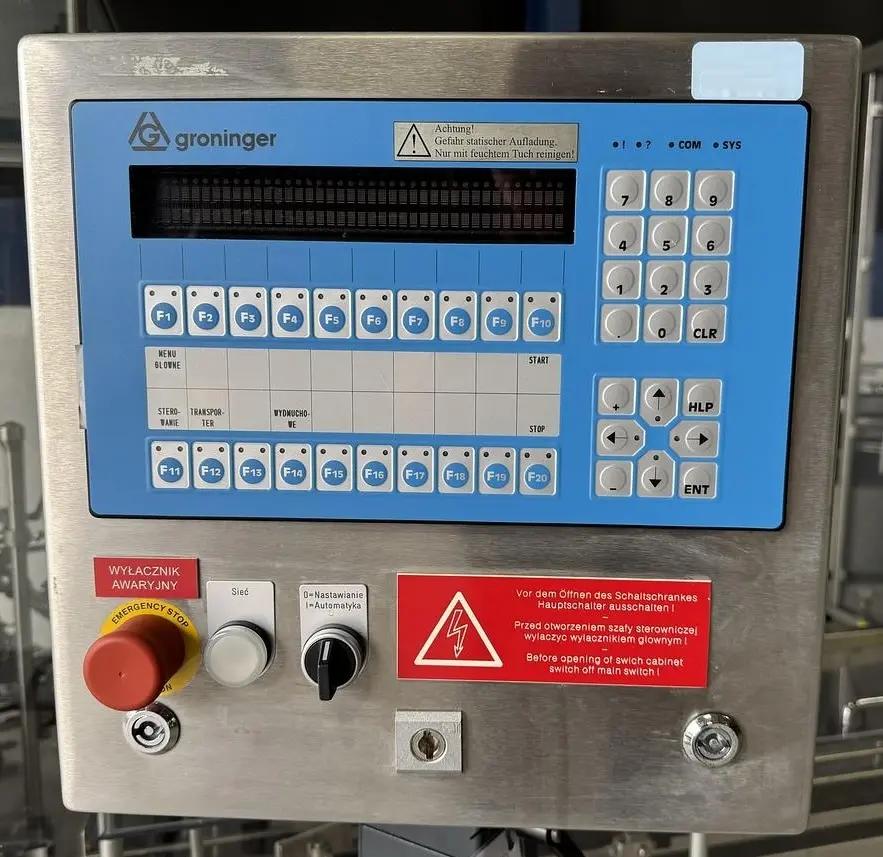

- Design antideflagrante (tutti i componenti elettrici all'interno e all'esterno dell'alloggiamento sono in versione Ex, il pannello di controllo principale è protetto contro le esplosioni tramite flusso di aria compressa; una caduta di pressione dell'aria inferiore a 4 bar provoca l'interruzione dell'alimentazione)

- Applicazione e chiusura di tappi spray a pressione o tappi standard a vite e a pressione

- Applicazione di atomizzatore - applicatore

- Applicazione sopra tappo

CARATTERISTICHE DI PRODUZIONE

- Produzione massima: fino a 60 BPM (a seconda delle dimensioni del contenitore e della soluzione di tappatura); Dosaggio fino a 260 ml

- Precisione di dosaggio per uso farmaceutico: +/- 0,5%

DIMENSIONI LINEA

- Larghezza: 3.000 mm

- Altezza: 2.700 mm

- Lunghezza: 8.500 mm

- Peso totale: 5.470 kg

composta da

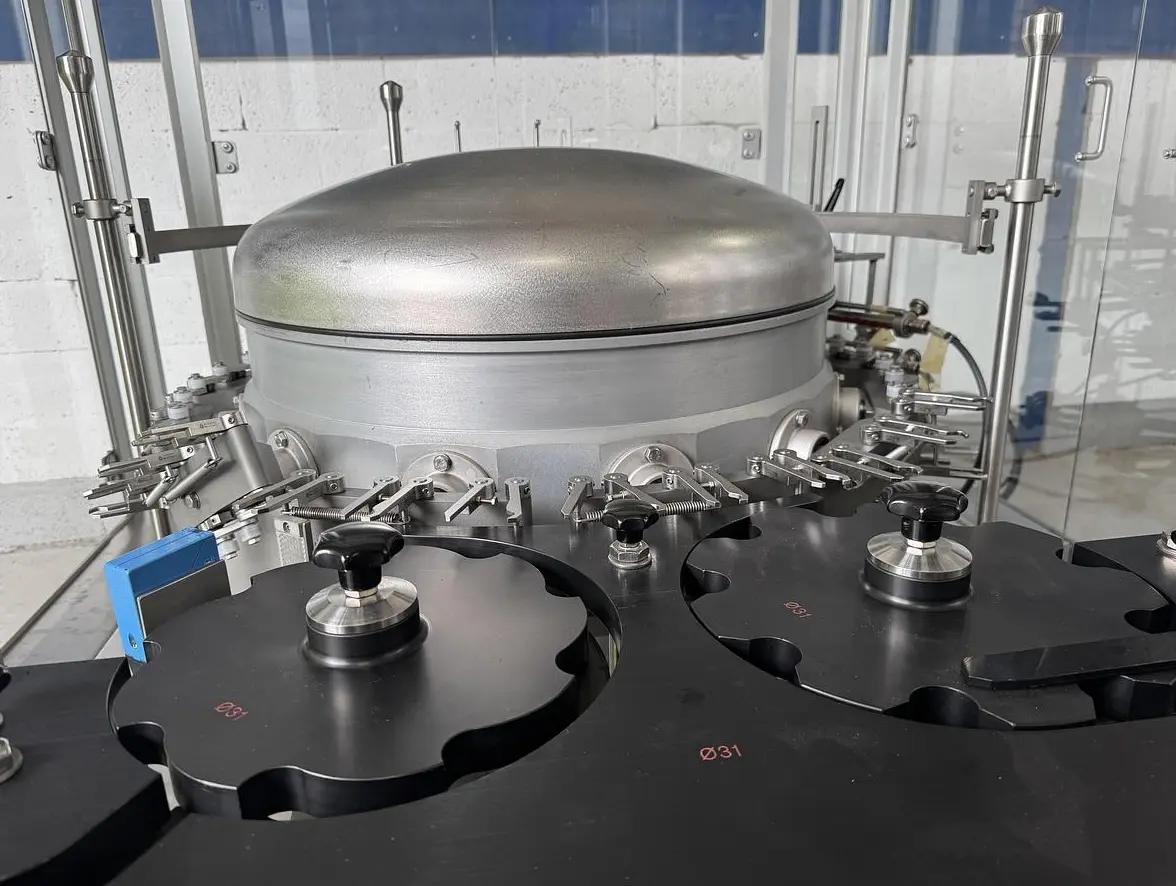

1) TAVOLA ROTANTE GRONINGER, MODELLO DTE-600

Smistatrice con caricatore di vassoi per bottiglie in vetro, dotata di piastre di alimentazione, spintore e coperchio. Progettata per la movimentazione di bottiglie in vetro e bottiglie in vetro con manicotti in PVC.

2) SMISTATRICE PER BOTTIGLIE GRONINGER, MODELLO ZSB-600

Anno di costruzione: 1997

Smistatrice per bottiglie in PE, con coperchio inclinato.

3) ELEVATORE PER BOTTIGLIE GRONINGER, MODELLO DE-100

Anno di costruzione: 1997

Per alimentare le bottiglie in PE alla smistatrice e all'unità di sterilizzazione e pulizia delle bottiglie.

4) UNITÀ AUTOMATICA DI STERILIZZAZIONE/PULIZIA FLACONI GRONINGER, MODELLO AAVK 300

Anno di costruzione: 2000

CARATTERISTICHE DELLA MACCHINA

- Velocità di lavoro: fino a 120 BPM se utilizzata come unità indipendente

- 12 pinze a 3 teste

- Stazione a 3 aghi

5) RIEMPITRICE E TAPPATRICE GRONINGER, MODELLO KFVG 201

Anno di costruzione: 1997

- con stazione di riempimento a 3 teste

- stazione di applicazione a pompa

- pre-serraggio e chiusura con pompe con testa a spruzzo e senza

- stazione applicatore-atomizzatore

- flusso laminare con filtri HEPA montati sopra la zona di riempimento e chiusura/tappatura

- quadro elettrico con controllore PLC

- impianto di pulizia automatica (CIP) con acqua di rete e acqua depurata a temperature fino a 40 °C