ROMACO NOACK - Linea Blister - N920 + C150 + PEWOPACK250 + CT2000

Specifiche

| Produttore | ROMACO NOACK |

| Modello | N920 + C150 + PEWOPACK250 + CT2000 |

| Anno | 2009 |

| Condizione | Usato |

| Numero di serie | MLTC-10-25-1853_25-1849_25-1845_25-1842 |

| Numero di magazzino | MLTC-0010-WH |

Descrizione

LINEA BLISTER ROMACO NOACK

composta da

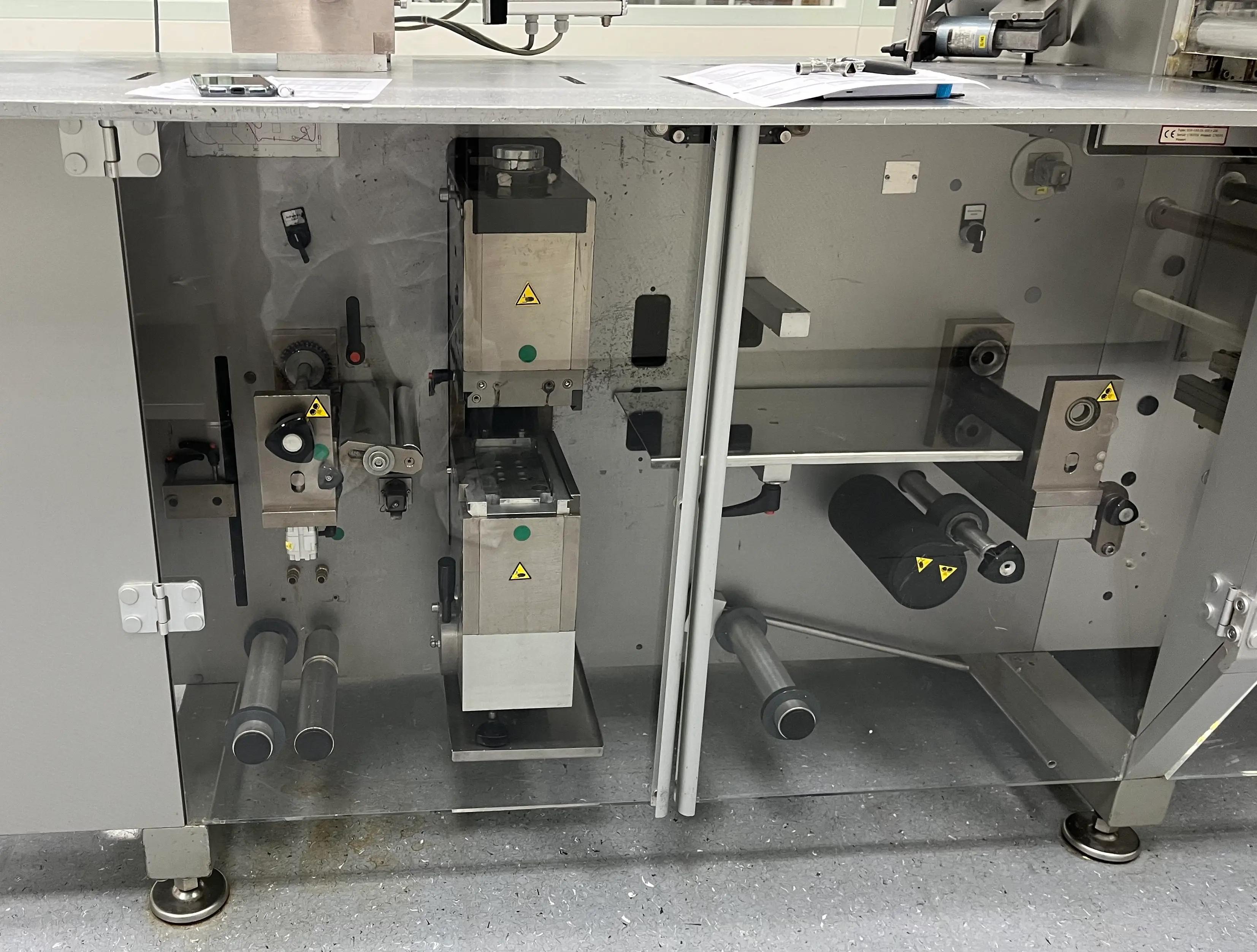

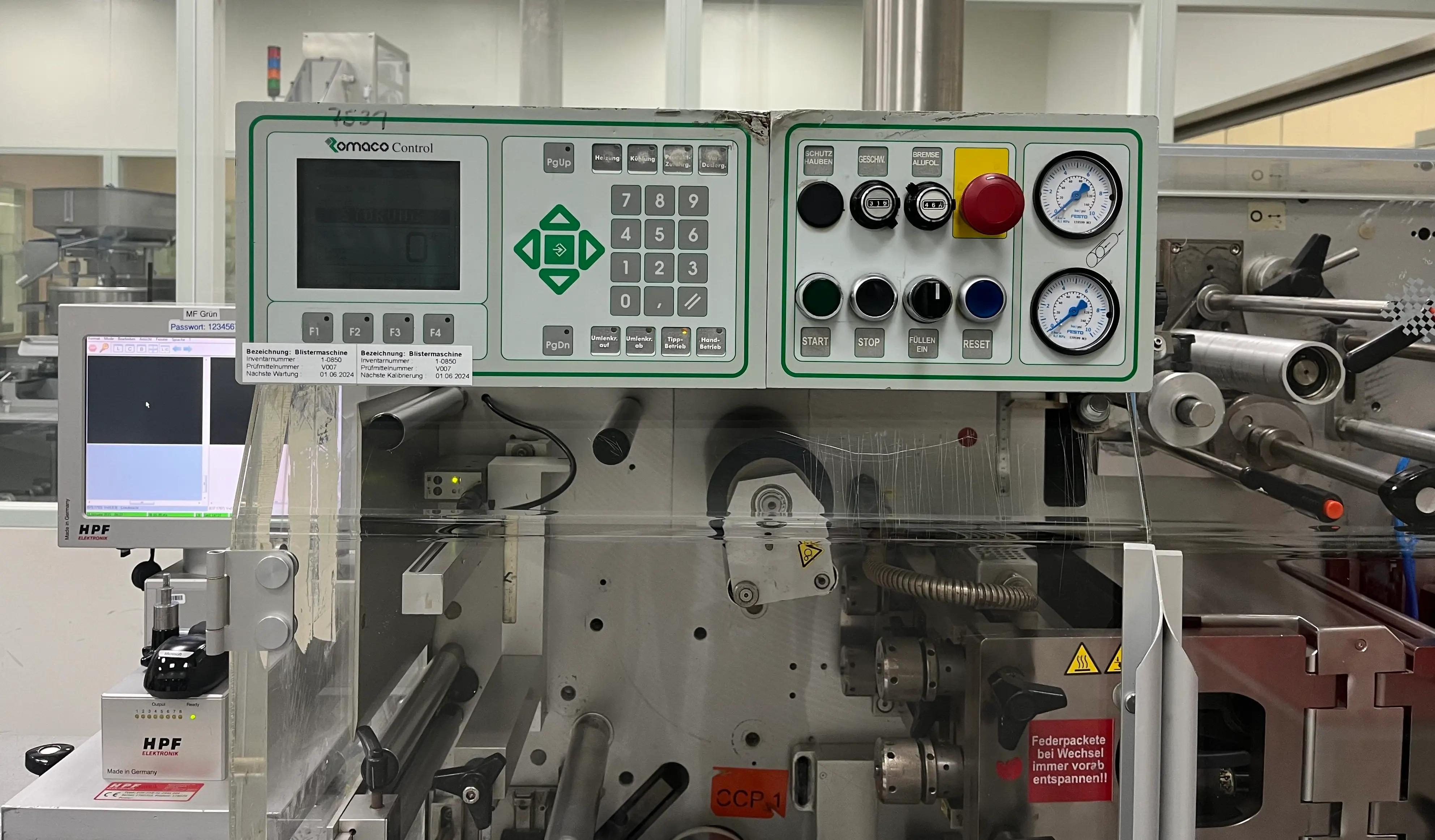

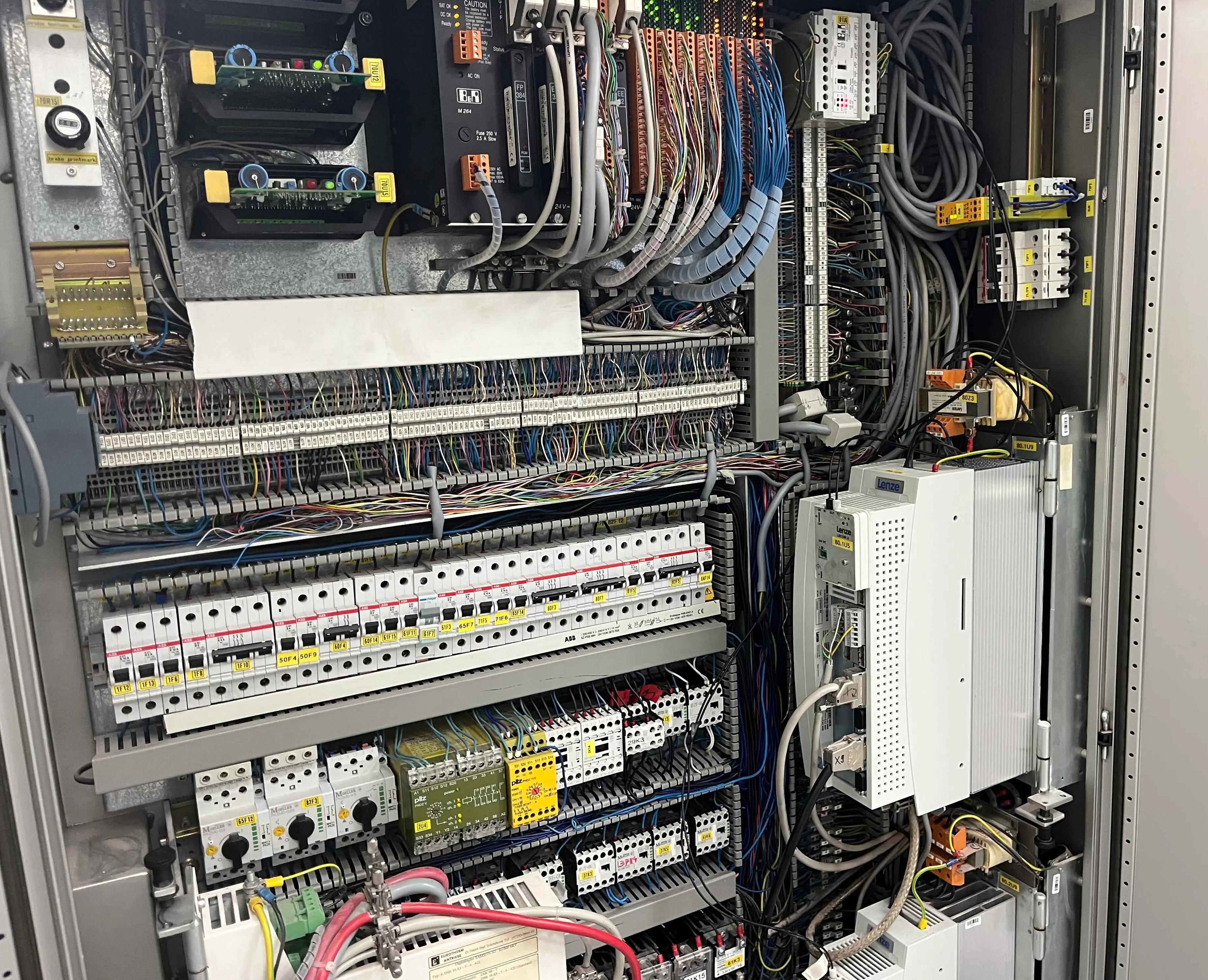

1) MACCHINA CONFEZIONATRICE ROMACO NOACK, MODELLO N 920

Anno di costruzione: 2010

Macchina blisteratrice rotativa. Con saldatore a 360°. Completamente conforme alle norme cGMP.

- Controllo XML con pannello di controllo touchscreen

- Con QuickFeed

- Design a balcone

- Facile integrazione di sistemi di stampa e sicurezza online

CARATTERISTICHE DI PRODUZIONE

- Produttività: fino a 500 blister/min

- Larghezza massima del film: 210 mm

- Profondità massima di formatura: 12 mm

- Cicli di formatura massimi: 100/min

- Diametro massimo del rullo di formatura del film: 700 mm

- Diametro massimo della bobina di film di rivestimento: 280 mm

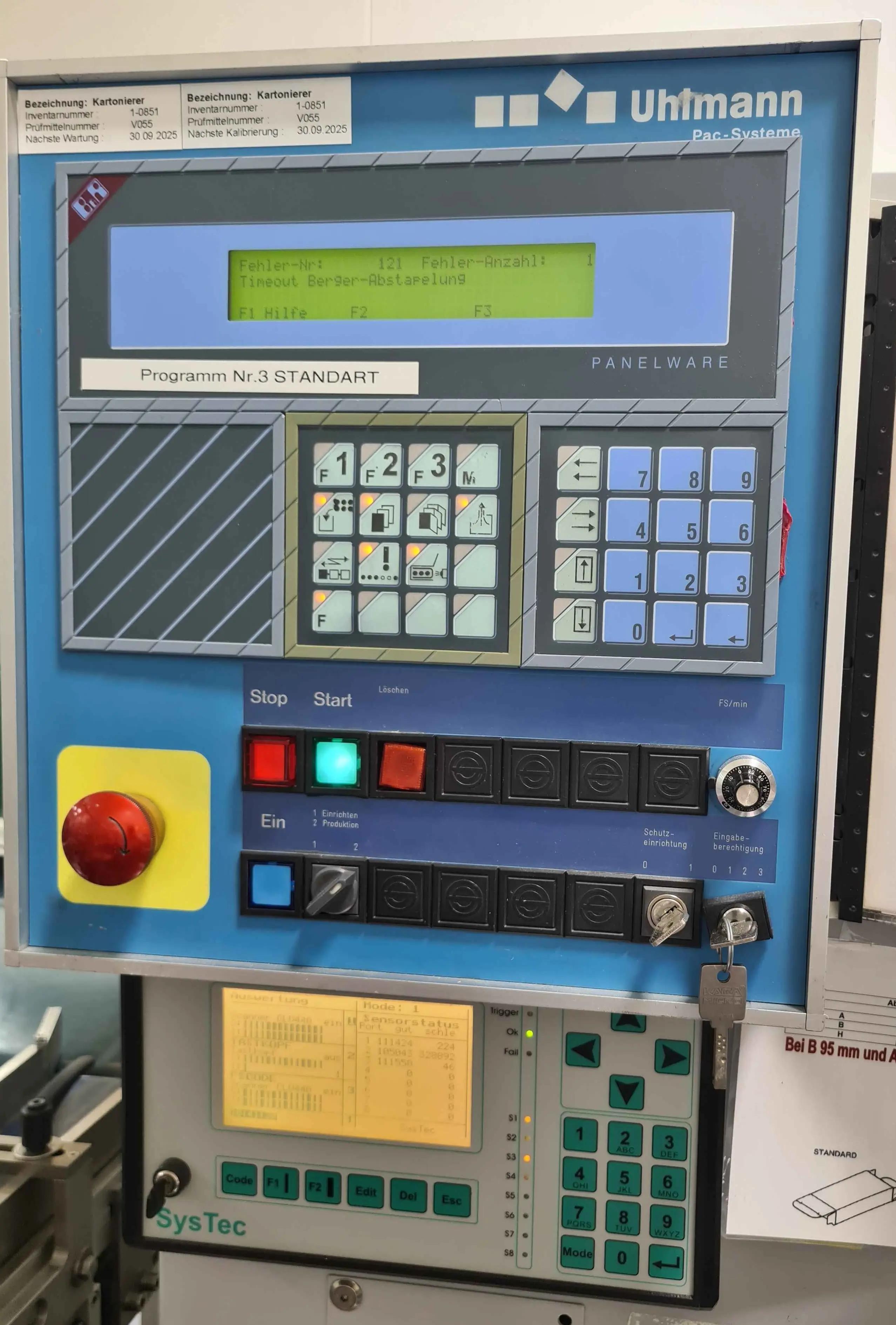

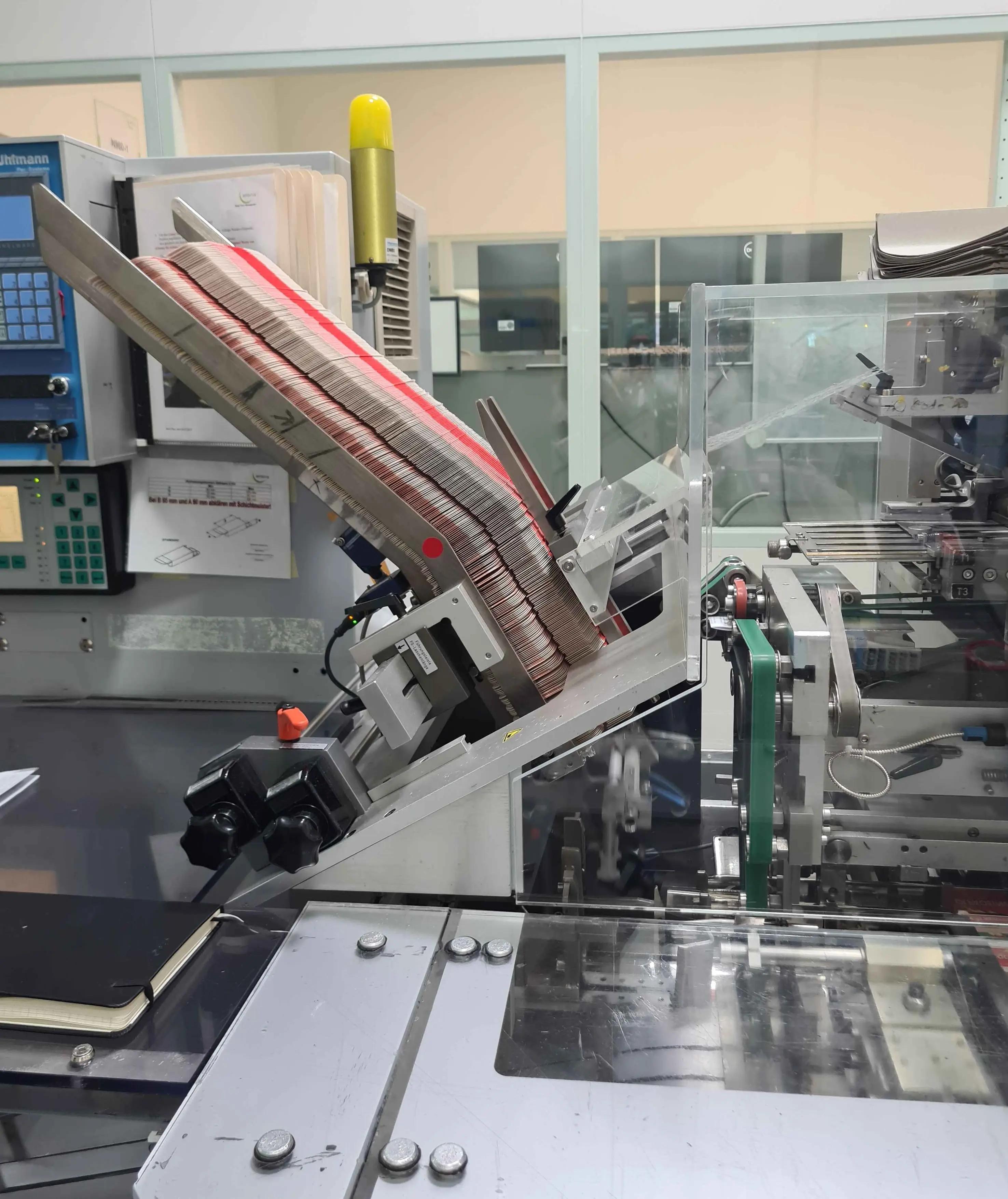

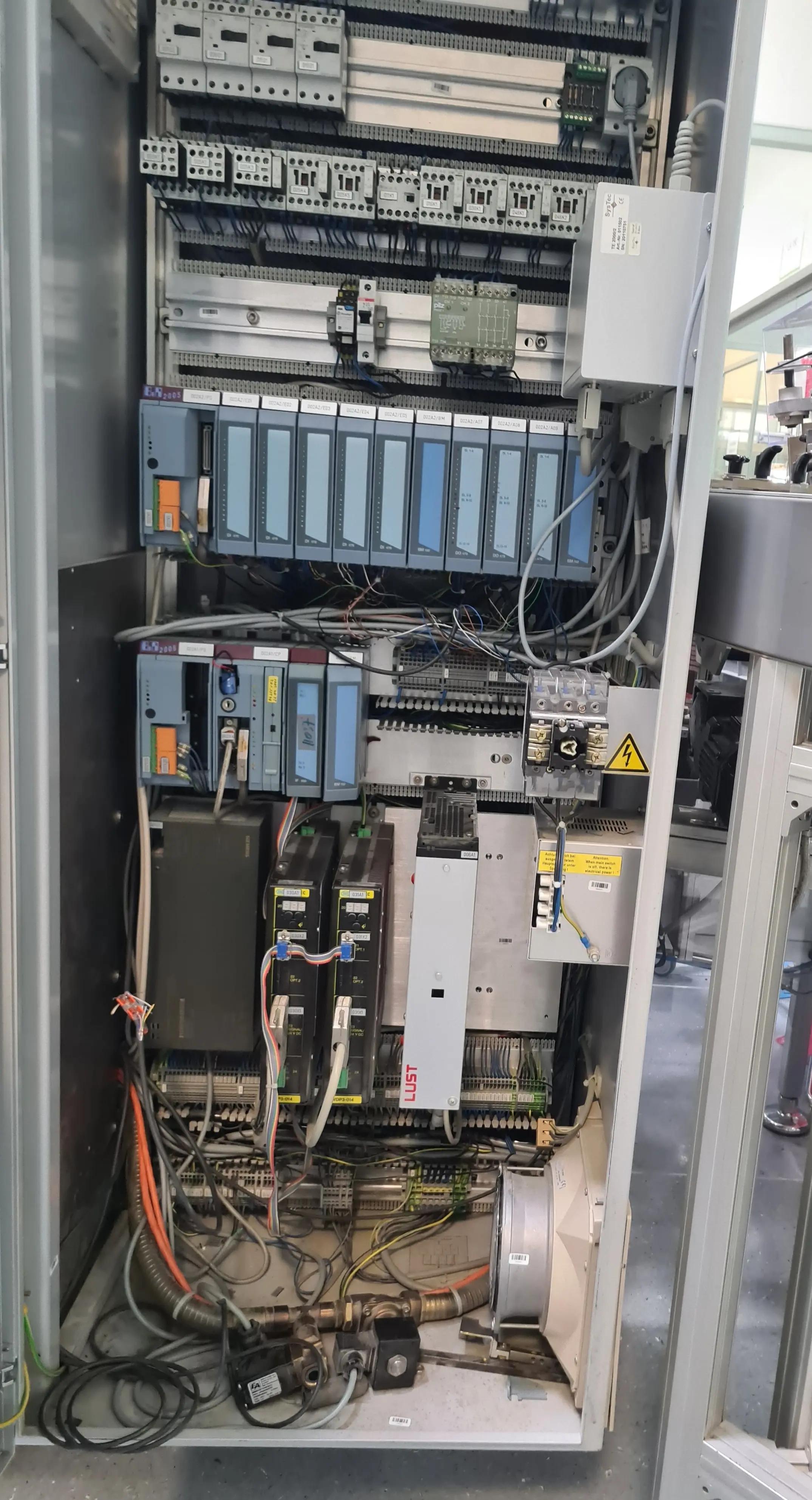

2) ASTUCCIATRICE UHLMANN, MODELLO C150

Anno di costruzione: 2004

Astucciatrice a movimento intermittente per lotti di blister di piccole e medie dimensioni.

CARATTERISTICHE DI PRODUZIONE

- Produzione: 150 astucci/min (max)

- Dimensioni massime astuccio: 100 x 85 x 150 mm

- Numero massimo di blister: 10

- Altezza massima della pila di blister: 80 mm

- Tipi di chiusura: Interblocco e colla a caldo

- Area di applicazione: Blister

- Tipo di funzionamento: intermittente

- Passo: 5''

3) CONFEZIONATRICE PESTER, MODELLO PEWO PACK 250:

Anno di costruzione: 2000

Confezionatrice automatica.

CARATTERISTICHE DI PRODUZIONE

- Produzione: fino a 80 astucci/min

- Dimensioni confezione: 60 x 30 x 60 mm (min); 360 x 180 x 250 mm (max)

- Larghezza film: min.: 50 mm - max.: 250 mm

- Spessore film: min.: 25 μm - max.: 100 μm

- Diametro rotolo: max.: 300 mm

CONSUMO ENERGETICO

- Alimentazione: 3x400V + N + PE / 50Hz

- Pressione di esercizio: 5 bar

- Film utilizzabile: PE

4) SALDATRICE, MODELLO T-4000

Per la saldatura superiore e inferiore. Con inclinazione automatica delle linguette. Adattabile molto facilmente alle dimensioni correnti della scatola. La regolazione può essere effettuata da entrambi i lati.

- Controllo della potenza con controller SOCO SYSTEM

- Manutenzione semplice ed economica

- Ampia gamma di accessori, ad esempio Ruote con freni, tavoli di confezionamento e nastri trasportatori

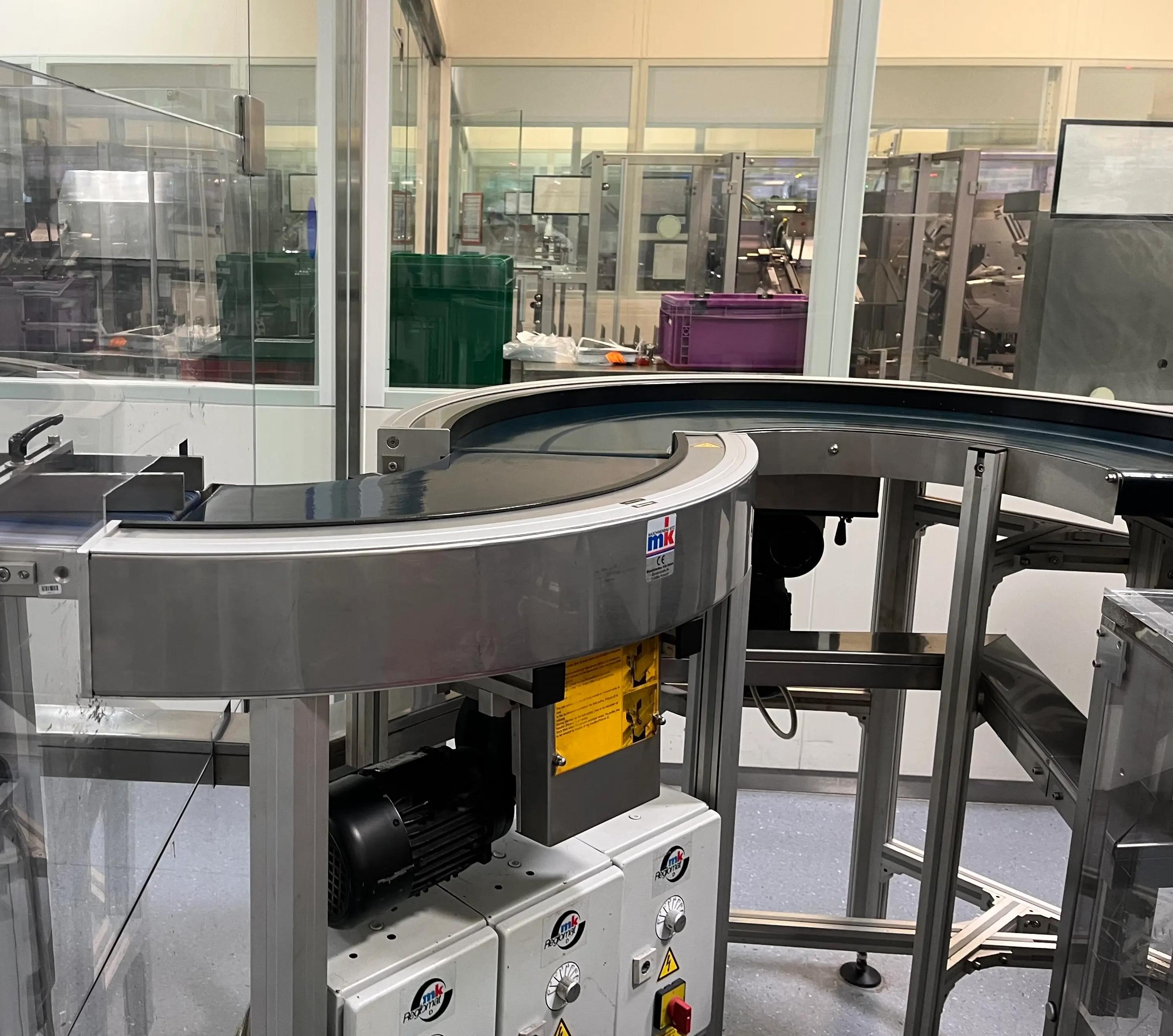

5) TAVOLO DI RACCOLTA CHRIST, MODELLO CT2000

Anno di costruzione: 2009

Tavolo di raccolta completamente automatico per lo stoccaggio temporaneo dei prodotti.

- Struttura in acciaio inox facile da pulire

- Design ergonomico con ampio spazio per piedi e ginocchia dell'operatore

- Design compatto e di alta qualità a balcone

- Riconoscimento automatico di tavolo pieno e arresto delle macchine a monte

CONSUMO ENERGETICO

- Tensione di esercizio: 1x230 V; 50 Hz

- Tensione di controllo: CC 24 V